Our business model is built around partnering with clients who share similar values and hold the same long-term commercial view as we do.

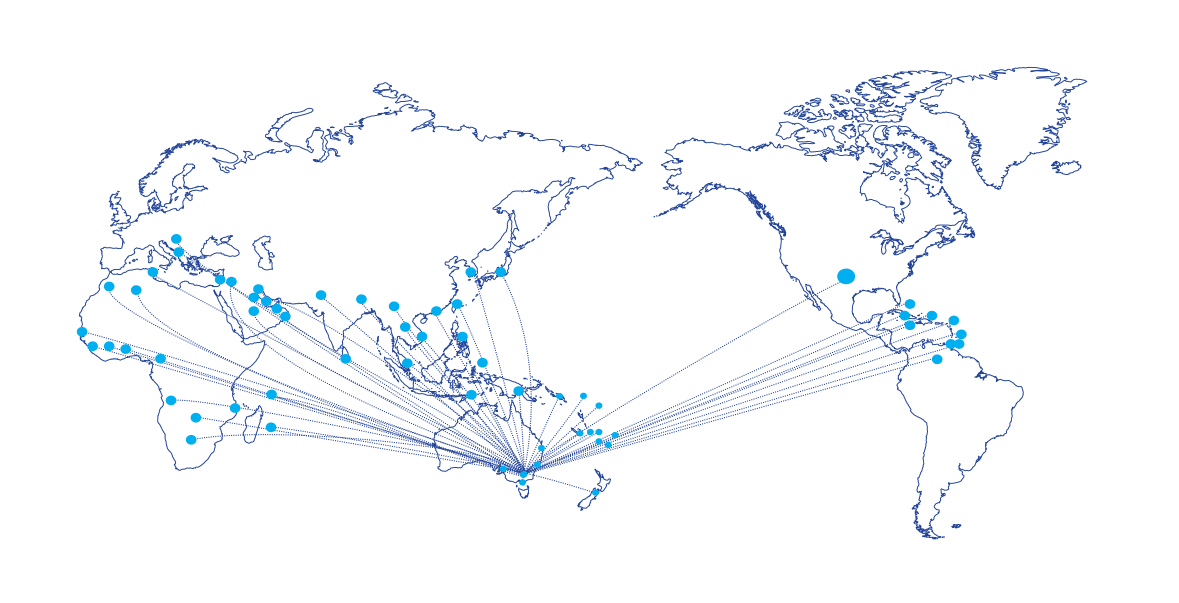

We focus on securing long-term strategic supplier partnerships where we know we can deliver real value. These close relationships also allow us to share knowledge and grow our understanding of our client’s emerging requirements. This means we can swiftly make changes to our operations to deliver services that match their changing needs. This may include a shift in consumer preferences that requires GMP to accommodate a new product line.

For more than 35 years, we have processed beef and/or lamb on a weekly basis for Coles Supermarkets. In 2000, this long-standing relationship became exclusive, with GMP becoming an Alliance Processor for the national supermarket chain based on our strategic location, competitive costing and unparalleled quality.